| tkCNC

Overview |

Screenshots |

Download |

Purchase |

FAQs |

Contact |

Online

Help |

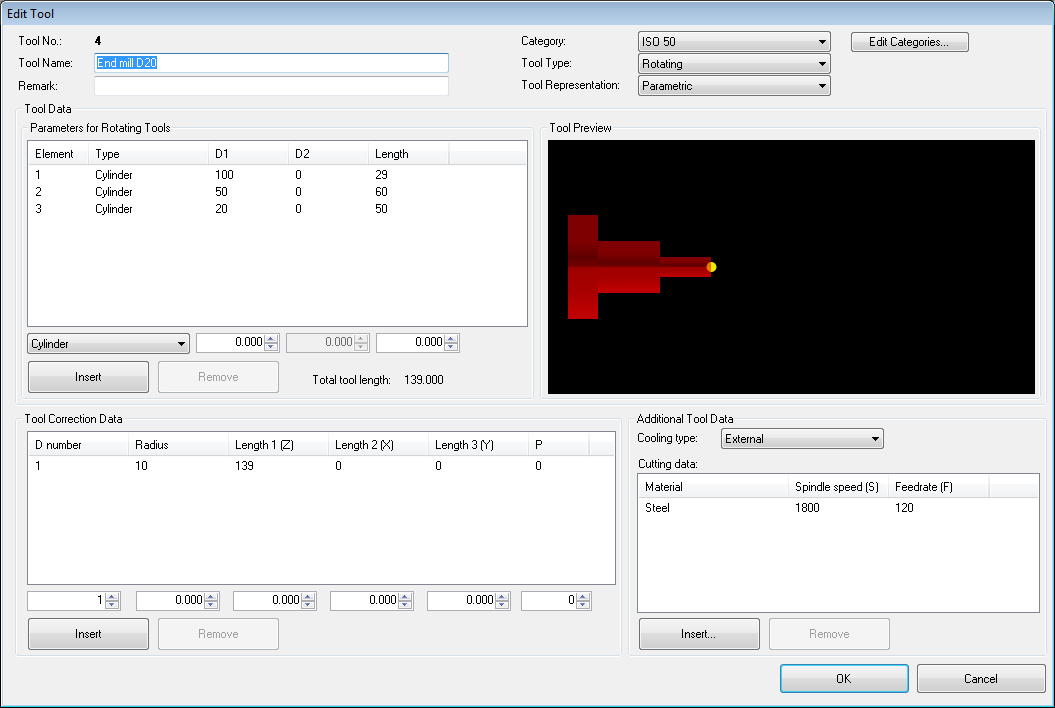

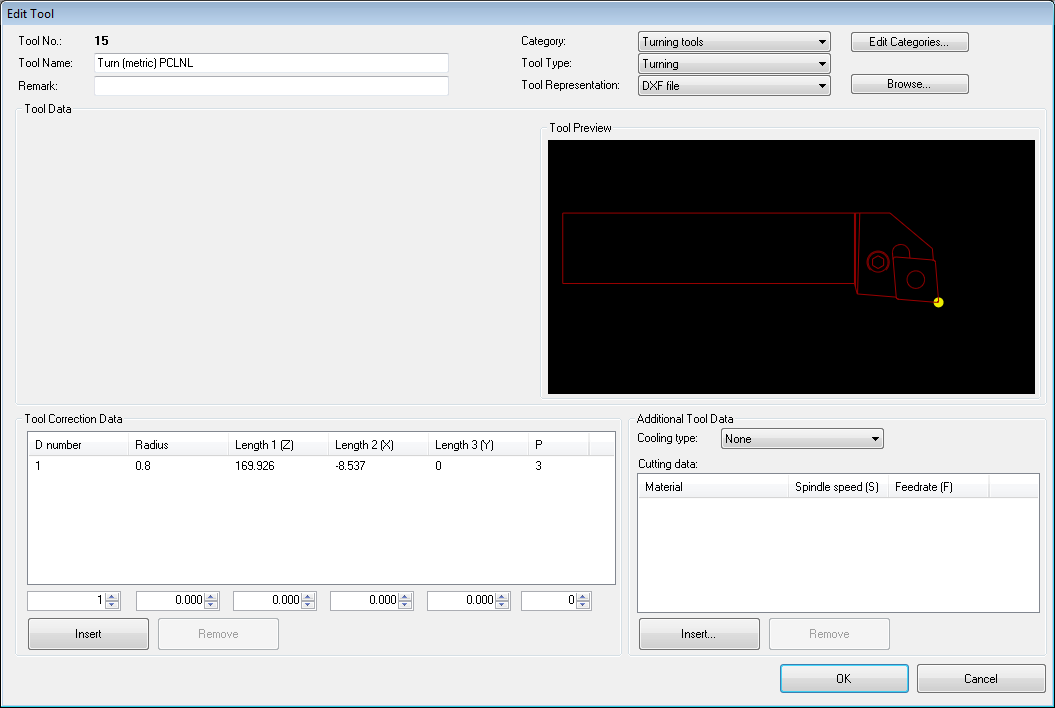

Edit tool

In Edit tool dialog you can edit all details for a defined tool.

- Tool name – enter tool name with basic tool data (diameter, tooltip radius…) e.g. "End mill D20x50"

- Tool remark – additional tool data

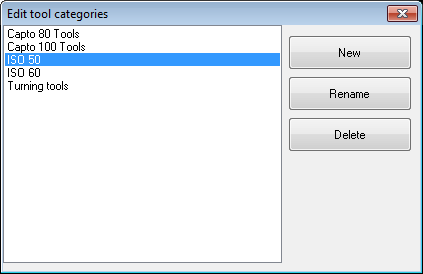

- Category – Assign tool category for a tool. Click on "Edit

Categories" to add new, rename or delete category (Note: Category can be

deleted only if there are no tools in that category)

- Tool Type – define tool as rotating or turning

- Tool Representation - Tool geometry can be defined as parametric (rotating tools only), as STL file and as DXF file (If STL or DXF is selected you can browse to that file)

- In "Parameters for Rotating Tools" area you can define rotating tool

with four simple elements: cylinder, cone, convex radius and concave

radius. Select element type and enter parameters for diameter 1 (D1),

diameter 2 (D2) (where applicable) and length. Use "Insert" button

to add element or "Remove" button to delete element from a list.

E.g., you can define drill with 1 cylinder and one cone element. See

already defined tools for examples.

As you add elements, "Total tool length" value is changing. - Tool Preview – displays current tool and correction point(s)

- Tool correction data – use this area for definition of one or more tool length correction points.

Tool correction data contains:- D number – correction number (usually 1, 2…)

- Radius – radius of a tool (for G41 and G42 compensation). Define this value for end mill or tip of turning tool. Not necessary for drilling tools.

- Length 1 (Z) – position of a tool length correction point in Z axis (from tool origin point) – enter this value for rotating (drilling and milling) tools

- Length 2 (X) and Length (Y) - position of a tool length correction point in X and Y axis (from tool origin point) – used for turning tools but Y value is 0 in most cases

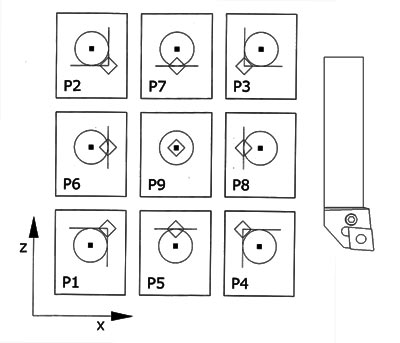

- P number – orientation of a turning tool according to this rules:

Note: In this rules tool default orientation is vertical, but in Tool preview tool is displayed horizontally (Z axis is horizontal)

- Additional tool data – in this area you can define tool cooling type and cutting data for different materials. Click "Insert" to add material and calculate cutting data. This cutting data can be used in tool change code insertion.

Example of turning tool definition:

tkCNC Editor - Your G-code editor