| tkCNC

Overview |

Screenshots |

Download |

Purchase |

FAQs |

Contact |

Online

Help |

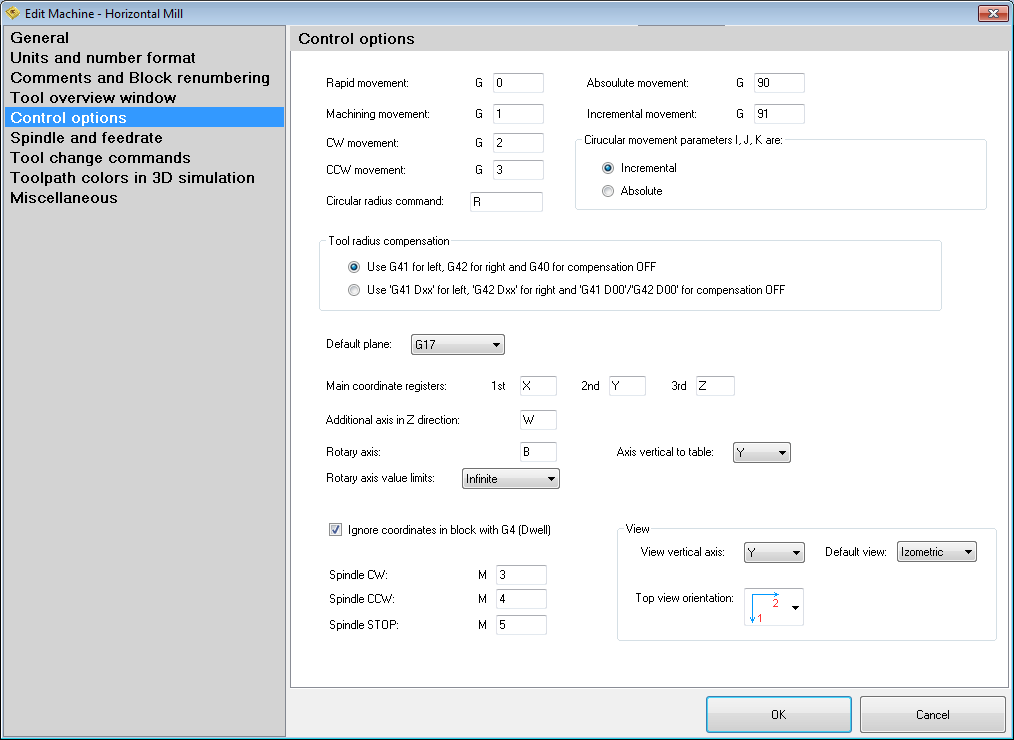

Edit machine – Control option

In this section you can define various options dependent of machine control:

- G movement commands (G0, G1, G2, G3)

- Circular radius command (how arc radius is defined in G2 and G3 moves)

- Incremental and absolute modes

- Mode for I, J and K registers for circular movements (older machines use absolute mode)

- Tool radius compensation mode (older machines use format e.g. G41 D10 to start tool radius compensation and G41 D00 to turn it off)

- Default plane (in most cases G17 for milling machines, and G18 for lathes)

- Main axis registers (default X,Y,Z)

- Additional axis for Z (some machines use W axis)

- Rotary axis – define register for rotary axis, if any, and define direction of rotary axis

- Rotary axis value limits – define if machine has infinite or limited rotary movement

- Ignore coordinates in block with G4 – if you use X register for G4 command this X will be ignored

- Spindle direction numbers (M3, M4, M5)

- View orientation (for 3D simulation):

- View vertical axis – define vertical axis for a machine (e.g. Z for vertical mills, Y for horizontal mills...)

- Default view – select default view on a scene when 3D simulation is started (Top, Front, Left, Right, Back, Bottom or Isometric)

- Top view orientation – defines how scene in 3D simulation is oriented according to top view

See also: Edit existing machine

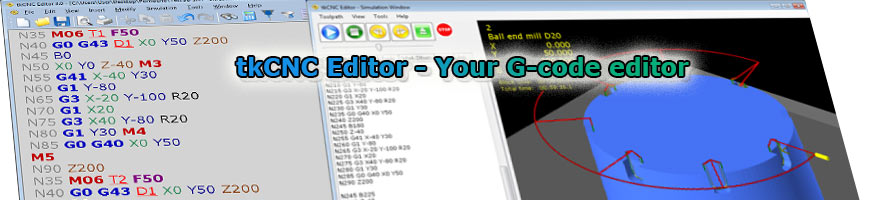

tkCNC Editor - Your G-code editor